Focus on fasteners to optimise design and performance

- Specify & Build

- Jun 16, 2025

- 3 min read

Brian Mack, Technical Business Development Manager at EJOT UK explains why early consideration of the fastening approach for a metal building envelope has far-reaching benefits.

When we think about the main products required to create aesthetically original, thermally superior and high-performing roofs and facades, fasteners may not be at the top of the priority list. Usually, specifiers focus on the types of panels and insulation that could be deployed, and the significance of the fastener’s role is overlooked.

Given the need for the construction industry to create a safer and more sustainable built environment, however, the crucial role fasteners play in achieving the performance goals of the building envelope is increasingly being realised. More certainty can be provided about the quality and performance of the envelope by focusing on the fastener specification early and not leaving decisions about these tiny components to chance.

Unlocking aesthetic potential

Careful fastener specification is not only about minimising the risks of issues developing – it could actually determine the form of the envelope as a whole. The fastener choice may not only influence the aesthetics of the building but actually offer a completely different perspective on the proposed envelope design or system choices.

This is possible with self-drilling EJOT Colorfast fasteners, which feature a nylon over-moulded head that can be coloured to match the panels it is fixing into place. More than 400 colours can be achieved in line with recognised colour matching systems, such as RAL, NCS, British Steel, and Pantone. The production process also allows for bespoke corporate colour matching, which opens up a whole world of possibilities from a branding perspective.

Types of metals used for fasteners

The majority of metal roofing and cladding sheets, composite systems and sandwich panels in UK projects are manufactured using steel or aluminium. That means the recommended fastener material will either be coated carbon steel, which is suitable for relatively low-risk environments, or stainless steel. The latter offers enhanced resistance to corrosion, making it suitable for a much wider range of applications, with a service life in excess of 40 years possible, depending upon the stainless steel grade and environmental classification.

Best practice for most projects is to specify stainless steel fasteners as these offer greater certainty in terms of resistance to corrosion. However, the most appropriate type of metal for the fastener depends on the application, and the level of corrosion resistance can be enhanced further when an over-moulded fastener like Colorfast is used. This is due to the way that the over-moulding process completely encapsulates the metal screw head with engineering-grade nylon to provide an effective seal from moisture.

Maximising air and water tightness

Every fixing point in the metal building envelope penetrates through the outer roof or cladding sheets. That’s why the installed fastener must provide a reliable seal to prevent air leakage and water ingress, which would undermine the building envelope’s performance.

Colorfast self-drilling fasteners have a high-quality integrated washer formed of EPDM bonded to aluminium, a design which helps to distribute an even clamp load when the fastener is driven into place. It ensures a tight seal can be achieved at the roof sheet, also compensating for moments when installation cannot be 100% perpendicular. Best practice is also for the quality of the self-drilling fastener seal to be tested at regular intervals during installation using a seal testing kit like EJOT VACUtest – something contractors are increasingly writing into their own quality procedures.

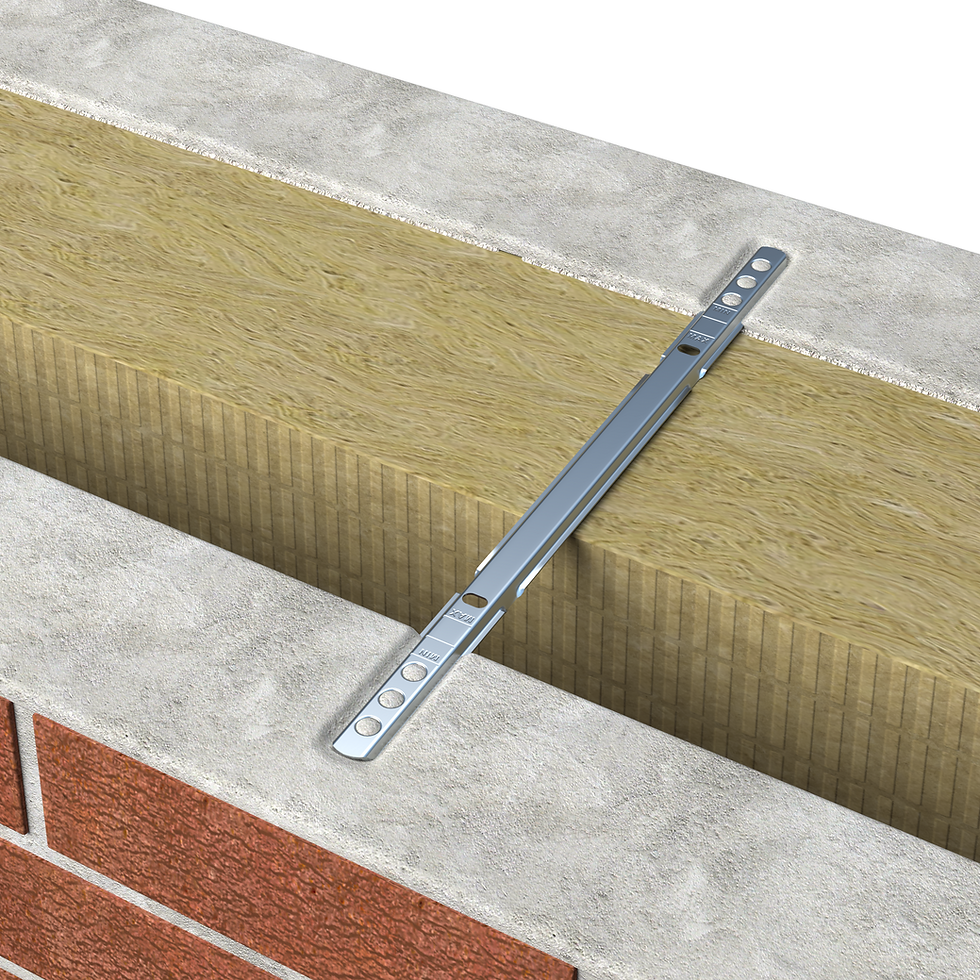

Building envelope structural considerations

Another reason why early fastener specification is recommended is because they also perform a critical structural role. Fasteners are subjected to a variety of loads including tensile, shear and installation, such as the fastener’s ability to resist overdriving. In cladding systems, resistance to bending and pushdown, and the ability to provide clamping, are also key factors.

This is why a well-designed fastener has further advantages, enabling installers to achieve the right results on site by giving them a clear indication when a correct clamp is achieved and reducing the risk of over-driving.

.png)